Step 1: Tap Test

Attach the accelerometer at the end of a milling tool assembly (solid carbide or indexable) and lightly tap the opposite side with the instrumented hammer. The sensor in the hammer records the force applied to the the tool and the accelerometer's response to calculate the tool point frequency.

Step 2: Generate a Dashboard

Our AI-powered system analyzes the frequency response function (FRF) generated by the tap test and that data is presented in an easy to read and interactive Dashboard. Find fastest stable speeds, feed rates, depths of cut, highest accuracy and best surface finish.

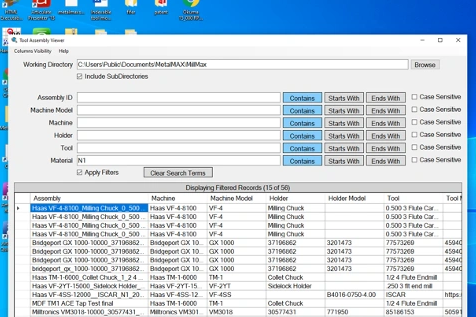

Step 3: Store Dashboards in Viewer

Store your Dashboards for your tool assemblies on your PC or server with our Viewer application. Search and retrieve by tool or machine as needed for a new job or RFQ.

Step 4: Compare Tools in a VirtualRunoff®

Select up to four tool assemblies and compare them in a VirtualRunoff® to determine the best tool, running the best combination of speed and tool path strategy. Use this data for your quotation.

Step 5: Write your Part Program

Open the Dashboard of a tool assembly and use it as a pop-up tool calculator and co-pilot for your CAM program. Optimize the cutting parameters in your database for stable first time right and first time fast part programs before you take a cut.

Step 6: Validate and Fine Tune with Harmonizer®

This is an extra step that is optional if you want to squeeze out every bit of productivity. Performing validation cuts with the Harmonizer smartphone or PC app listening may allow you to cut a little deeper and adjust for instability caused by the workholding or other factors.

Innovation Park at Penn State University - 200 Innovation Boulevard - Suite 242A - State College, PA, USA

Copyright © 2025

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.