Cutting Tools for Milling Manufacturers

Tap Testing for Tooling Manufacturers

Now available.

eAmerica's largest metalworking distributor continues to offer tap testing as a service. Our five year exclusive agreement with them has ended and we are now free to offer the very sam award winning solution under our own brand name of SpeedCast tap testing kits and UNLIMITED AI-generated Dashboards.

Over five years and thousands of tap tests the following results were published:

- 200% increase in feed rates

- 300% increase in metal removal rates

- 50% decrease in cycle times

Get started today

Fill out the pricing request form below and we will provide you with a quotation for a kit and software.

Imagine if your tooling came with Dashboards

Unlimited Dashboards

Generate as many Dashboards as you want. It takes less than one minute to generate a Dashboard at the spindle after a tap test.

Dynamic Speed and Feed

Paper speed and feed data are very conservative and static. Dashboards are dynamic and based on the tool assembly and machine combination's unique characteristics.

Pop-Up Calculator

The AI-generated Dashboard from a tap test serves as a comprehensive pop-up calculator for your programmers.

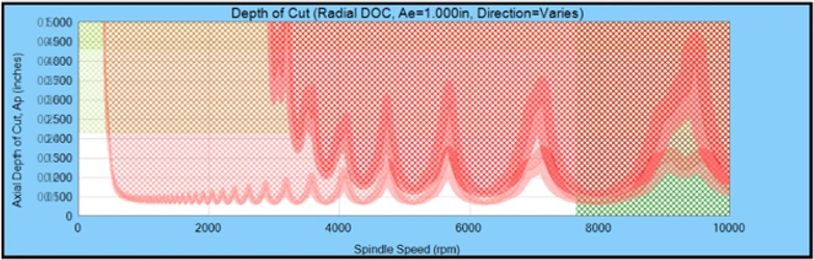

Find Stable Speeds

The speed dial shows stable speeds in green and unstable in red. Change the width and/or depth of cut and the dial adjusts instantly.

Surface Location Error and Surface Finish

Because we measure the tool's dynamic displacement, you can find speeds that will generate the best surface finish and accuracy.

Calculations and Conversions on the Fly

The Dashboard calculates metal removal rate and power. It instantly converts from inch to metric, RPM to SFM, IPT to IPM and WOC to %.

Know before you cut

You can try different scenarios and tool path strategies before ever taking a cut. Try out a sample Dashboard by clicking below.

"If I speed them up, I will sell less"

The conventional, if unspoken, wisdom is that tap testing speeds up milling therefore fewer cutting tools will be used and so that is why the industry has not adopted it widely. However, what if this assumption was wrong? The chart on the left shows the typical cost of a machined part as cited by Sandvik Coromant. The cutting tools are the smallest category at only 3%. Over the past five years published statistics have shown that our tap testing kits and software have yielded an average 300% increase in metal removal rates and a 50% reduction in cycle times. In other words, if you made one part an hour before tap testing you now made two after tap testing. Now let’s apply the Taylor equation for tool wear. An increase in tool velocity should then increase tool consumption. But do we really care? The tool costs jump to 12%, but the doubling of production generates a 31% savings! Yes, faster tool wear will require more tool changes, but that can be dealt with redundant tools. McKinsey reports that the cutting tool market for milling in the U.S. is $1.9 Billion.

Does tap testing have the potential to quadruple the size of that market (and for toolholders to hold those redundant cutters) to nearly $8 BILLION while doubling America’s machining capacity?

Use the interactive chart below. The slices of this pie chart show the costs of a machined part as above, both fixed and variable. First, move the left Tooling Cost slider to the left where it says "free". The red slice that appears is the impact on part cost if you were to give the customer their tooling for no cost. Return the left slider to the middle or "current cost". Now, move the right Productivity Increase slider to the right, to about 50%. The red slice grows very large. Now, move the left slider all the way to the right, effectively doubling the cost of the tools. The red slice remains quite large, illustrating it is not the cost of the tool, but how it well it performs that makes the largest impact.

Why use Tap Testing?

You can't improve what you don't measure.

The chart at the left shows the same endmill sticking out the same amount in six different premium toolholder types in the same machine tool and in the same material. Each were tap-tested and the results validated with cutting tests The difference from the best to the worst was nearly 5X. If you also make toolholders, consider this: an endmill with a different number of teeth and length was tested and the winning and losing toolholders from this test were different.

Tap Testing Benefits for Tooling Manufacturers

Just Milling?

Price per Part vs. Price per Tool

Milling is the largest cutting segment accounting for 40.3% of all tools purchased. It also removes the most material and therefore has the largest impact on your customer's profitability. It is the most difficult of all metalworking applications and is prone to chatter. Win milling and you win the customer.

Price per Part vs. Price per Tool

Price per Part vs. Price per Tool

Tap testing will show your customer the value of increasing performance rather than focusing on the purchase price. Cutting tools will transform from a commodity bought from the lowest bidder to a highly engineered solutions. You will be able to increase your profit margins.

Sell More Tools

Speeding up will not cause you to sell fewer tools. According to Taylor's Equation higher velocity increases tool consumption. They will buy more endmills and inserts, along with more cutter bodies and toolholders for redundant back-ups. They will be more competitive and win more work.

Upload and Train your Data

Upload your tooling data with the correct attributes (variable pitch, variable pitch, chipbreakers, etc.) to ensure accurate predictions by all SpeedCast users. Train our models with your unique geometries for even more accurate performance predictions and thus create customized, dynamic speed and feed charts. See information below.

Reduce Inventory

Controlling chatter and creating stable, robust processes will reduce the need for safety stocks in vending machines and on your shelves. Consumption will be more predictable and consistent month to month.

Resharpening Tools

If you offer resharpening or special tools, tap testing is a vital service. You can tap test new and resharpened endmills to find a stable speed for both so both can be co-mingled in inventory. No more huge performance drop offs with regrinds.

Tool Tuning

Reduce Cost of GTO's

Sell SpeedCast

Every endmill manufacturer should learn the concept of "tool tuning". By adjusting the amount of the endmill stick-out, guided by tap tests and AI Dashboards (generated in less than a minute) you can manipulate the stable speed lobes or zones.

Sell SpeedCast

Reduce Cost of GTO's

Sell SpeedCast

You can resell SpeedCast tap testing kits and software subscriptions to your customers. We off reseller discounts. Fill out the form at the bottom of this page to get a quotation.

Reduce Cost of GTO's

Reduce Cost of GTO's

Reduce cost of Guaranteed Trial Orders (GTO). Use tap testing to predict outcomes and to adjust configurations to score more wins. Toolholders and indexable bodies supplied for failed trials cannot be resold as new. Use tap testing to if a trial order is warranted before committing.

Select Right Toolholder

In a study of the same endmill in six different premium toolholders, performance ranged 5X from best to the worst. You can be either five times better or five times worse based on the combination you chose. Tap testing enables you to evaluate a tool assembly prior to taking a cut and guides you through optimization.

Catalog Chart vs. Dashboard

Catalog Chart vs. Dashboard

In this study the same tool was compared using speeds and feeds recommended by the chart in the manufacturer's catalog. The tool chattered and need to slow down to be stable. The same tool was tap-tested and the Dashboard provided parameters that improved metal removal by a factor of five.

Blueprint Specials

Catalog Chart vs. Dashboard

Special tools have no historical speed and feed data. Tap testing will give you the correct parameters before the first cut.

Frequently Asked Questions

Click the CONTACT tab if you cannot find an answer to your question.

Unlimited.

Having your tool database in our system makes it easier for users to access and test your tools. The databases included with every kit were scraped from websites or paper catalogs. Some SKUs and tool attributes may have been missed. While still able to provide actionable results in Dashboards, they might be fully optimized. Ensure they are by providing your data whether you have a kit or not.

It is very easy to learn and use. Here is a video. We have a comprehensive online training program that has be successfully used by over 200 individuals. Basic training takes just a few hours. If a CNC machine tool is not available to train with, a Bridgeport or drill press will also work. Our SimpleMilling™ application makes it very easy to take the first measurement.

Tap testing is a proven and validated technology, so we don't need to offer free trials. We do offer a $1250 30-day rental.

SpeedCast is exclusively for milling.

Staggering the teeth or varying the helix angle does make an endmill immune to deflection and vibration. They are not 100% rigid. They still have speeds that are good and speeds that should be avoided. They still have depth of cut limits that can be optimized using the combination of tap testing, Dashboards and Harmonizer.

Damped toolholders lower the frequency of vibration but do not eliminate them. Tap testing damped holders will reveal good and bad speeds. Also, damped holders are very long and suited for deep applications at slower speeds.

The kits are guaranteed for as long as your subscription is active. If your kit fails during that period, we will replace it via our Repair-by-Exchange program. The guarantee does not extend to consumables (cables, tips, wax and glue) or to replace lost components.

Wec have a chat function under the SUPPORT tab that will answer most questions and those it cannot will be immediately escalated to a live support engineer.

Stable cutting will produce equal tooth impacts and that will result in longer tool life, perhaps considerably longer tool life. However, if we employ faster stable speeds, faster than the catalog values, we may, based on the Taylor equation, see shorter tool life but with much higher productivity. You will have to weigh the results and decide a speed vs. tool life strategy.

According to a sales training agency, a field sales application engineer’s total costs are $85 per hour. Assuming that at least one endmill will be run to failure during the test (at your cost), a selling price of $100 per tool with average gross margins, you will have to sell 25 endmills before you breakeven, ONLY IF your new tool performed better. A 5 minute tap test (employee cost: $6.25) will tell you instantly if you can run faster or not, BEFORE you made a cut. As soon as you do that tool cannot be resold s new.

Yes, you can delete any tool or toolholder databases from the kits you use or those you sell to customers.

Yes, once validated for resell pricing you can buy kits and subscribe to software for your own use at those prices.

Request Pricing

Whether you use tap testing or not, others will and you want your data to be correct. It's free.

SpeedCast Database Upload Templates

You can customize your kits to include your tooling databases for ease of lookup and better performance predictions by all SpeedCast users. For example, our algorithm will improve if we know the tool has chipbreakers, a variable pitch or helix. You can select inch or metric. Download the excel templates and enter your tooling data. Email the spreadsheet to dbarton@deepmill.ai

Next Gen: provide us with your STP files

We are developing the next generation of machining dynamic solutions we are developing with the Oak Ridge National Laboratory's Manufacturing Demonstration Facility. Be a part of it by providing us 3D STP files of your toolholders and indexable tool bodies (with inserts).

Use your SKU for the file names.

Why you should train our models.

The stable speeds from the tap test do not change, but training our material models will increase depth of cut limits and increase the process damping low speed stable range. The Dashboards with your tools will show their maximum performance capabilities.

How to train our models.

Use this procedure to train our cutting force algorithms*

*Requires SpeedCast kit and software. You can rent a kit or use SpeedCast Lite.

Innovation Park at Penn State University - 200 Innovation Boulevard - Suite 242A - State College, PA, USA

Copyright © 2025

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.